Watch the Trailer. Take Action. #ToxicsFreeElectronics

The Global Samsung Unsustainability Report

Investigative news reporters at Korean media outlet, Hankyoreh, visited nine cities in India, Indonesia, and Vietnam and surveyed more than 120 workers at mobile phone factories over a 70-day period to develop an investigative series they call, “Global Samsung: A report on unsustainable labor practices.” The series asks questions about the life and work of company workers in Asian countries that host its major bases of production. The series assesses Samsung Electronics’ sustainability as a top-tier global company and describes its results as “unpleasant truths.” Learn more here.

At-A-Glance

Electronics such as mobile phones, computers and TVs are blockbuster consumer products, but their manufacture relies on and uses more than a thousand chemicals and other materials. Many of these are hazardous and lack comprehensive health and safety information due to weak regulatory policies. This causes harm in production, exposes consumers to toxic chemicals during use, and releases toxic chemicals when products become electronic waste.

As the global hub for electronics production shifted from the US to Asia, the industry also outsourced toxic chemical use as production soared. By the mid-1970s, there were about one million workers in electronics assembly in Asia, and 90% of them were women. Toxic chemicals used in electronics production include solvents, metals, and persistent organic pollutants, such as certain flame retardants, endocrine disruptors, carcinogens, mutagens, and reproductive and developmental toxicants.

Chemical threats to human health in electronics production and e-waste have been well documented in scientific literature. Severe illnesses including cancer, lung disease, reproductive disorders, congenital anomalies in offspring, and musculoskeletal problems arising from repetitive motion have been identified in manufacturing facilities located in China, Korea, Malaysia, and elsewhere.

Electronic products should be designed and produced in ways that eliminate their potential for human toxic exposure throughout their entire life-cycle, including during their manufacture, use, recycling and/or disposal.

A Global Issue of Concern

UN international policies include recommendations for eliminating and managing hazardous chemicals in the lifecycle of electronics. In 2009, more than 100 governments under the Strategic Approach to International Chemicals Management (SAICM) agreed that hazardous chemicals in electronics is an issue of global concern. In 2011, the United Nations Industrial Development Organization (UNIDO), and the Secretariats of the Basel and Stockholm Conventions hosted an expert group meeting to develop recommendations to address hazardous chemicals in electronics that were subsequently endorsed by more than 100 governments at SAICM meetings in 2012 and 2015.

South Korea – The human face of harm in South Korea’s electronics industry

Supporters for the Health and Rights of People in the Semiconductor Industry (SHARPS)

SHARPS has identified more than 300 cases of severe and often fatal occupational diseases liked to the electronics industry, including giants such as Samsung. SHARPS decided to develop a visual record of electronics industry victims by making a film featuring the voices of former workers and their families. Twenty-three people share their visceral stories about common chemical exposures in electronics production in “Stories from the Clean Room.” In June 2017, the film stunned lawmakers as it premiered in South Korea’s national parliament. Showings in more than 20 countries are planned in 2018 and beyond.

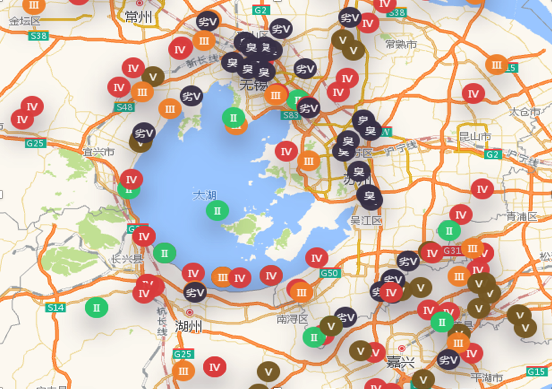

China- Public right to know about electronics industry emissions in China

Institute of Public and Environmental Affairs (IPE)

China is a global hotbed for chemically-intensive electronics manufacturing. Inventories of chemical releases known as Pollutant Release and Transfer Registries (PRTR) are a key chemical safety measure for industry accountability. IPE and IPEN jointly released the report, “PRTR: Establishing a Pollutant Release and Transfer Register in China,” on May 8, 2018 in Beijing, China. The report introduces voluntary disclosure efforts and emphasizes the importance of establishing a mandatory PRTR system with publicly accessible information. The two organizations also convened a discussion with representatives from academia, business and environmental groups on using a PRTR disclosure system to strengthen the management of hazardous chemicals.

Vietnam- Women workers in Vietnam’s electronics industry

Research Centre for Gender, Family and Environment in Development (CGFED)

The electronics industry occupies the #1 spot in Vietnam’s export economy and women in their twenties represent 80% of the workforce. CGFED and IPEN published a unique study based on interviews with 45 women workers who assemble mobile phones at the two largest Samsung factories in the country. Documentation of illegal practices, lack of regulation, and a variety of health impacts led to global awareness. Human rights experts from the UN Office of the High Commissioner for Human Rights voiced concern over Samsung Electronics’ threats to workers and researchers and efforts to suppress the report.